Bosch Motor Gen4 Performance Line CX – UPGRADED (Brand New)

$1,058.80

|

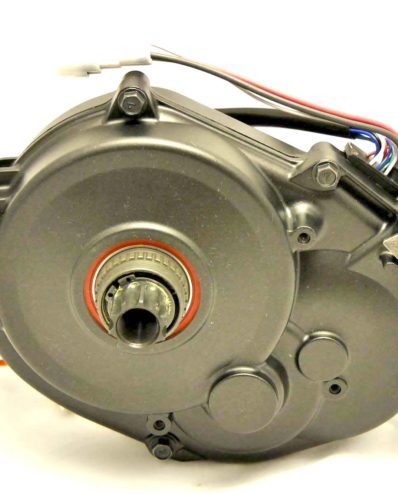

Brand new Bosch Gen 4 eBike Motor BDU480 CX 20mph Performance Line CX eBike Motor 20mph model. Can be factory programmed for any US bike originally equipped with this motor. Programming is very important for your motor to behave correctly. There’s a lot the motor needs to know about the bike it is in. Most motors purchased online will not perform as expected with it’s current programming parameters and in some cases will have no programming at all and will not work in any bike. We can clone your current motor software and firmware and even match you bike serial number with a new motor. Also, we can offer core swap to discount the price if the old motor is available.

|

Brand new Bosch Performance Line CX eBike Motor. 20mph model. Can be programmed for any bike originally equipped with this motor. We can clone your current motor and offer core swap to discount the price if the old motor is available and unrepairable.

Bosch Gen 4 eBike Motor BDU480 CX 20mph Fully Programmed (new)

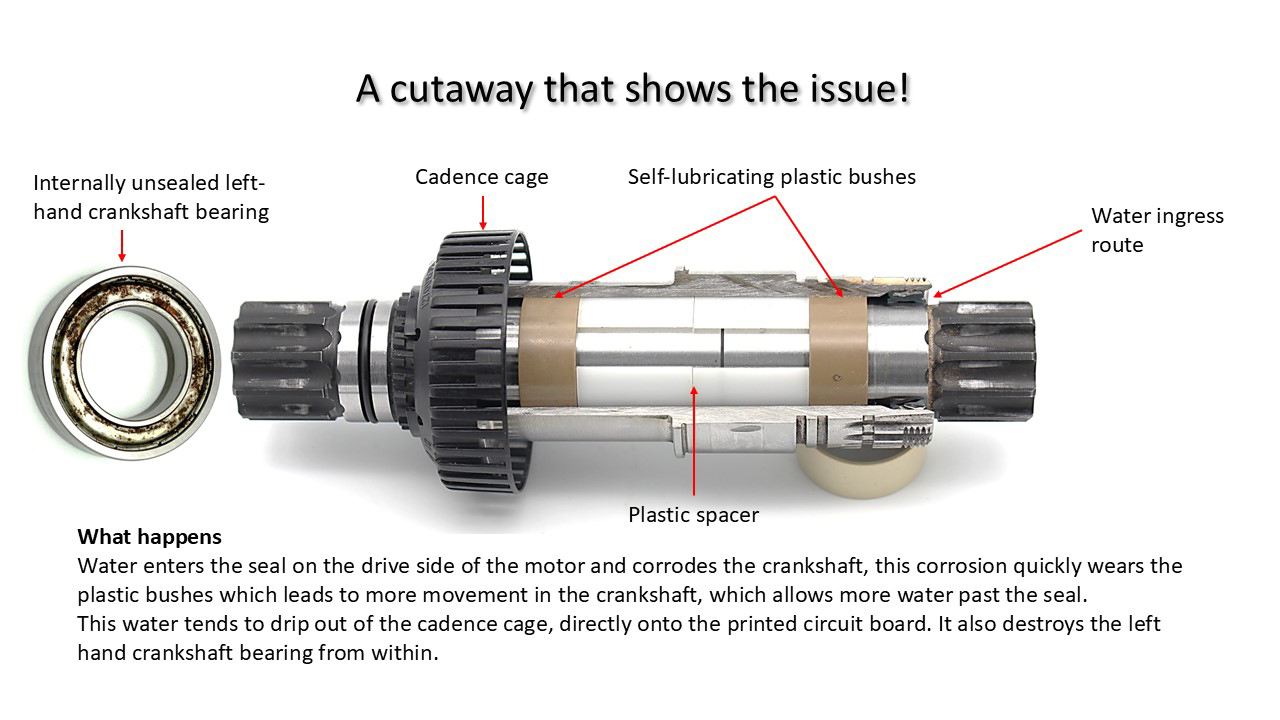

At eBike Motor Repair we noticed a failure pattern on the Bosch Generation 4 motors when used on EMTB’s. We could also see from our own experience, and the sheer number of Bosch Gen 4 motors going through our workshop, there were a few issues that needed addressing, particularly when used off-road. Although Bosch have been working hard to address some of these issues, that does not really help those outside of the warranty period. So, like our Brose upgrade, we decided to do something about it!

We now offer an upgrade for all Bosch Gen 4 motors. This includes the following:

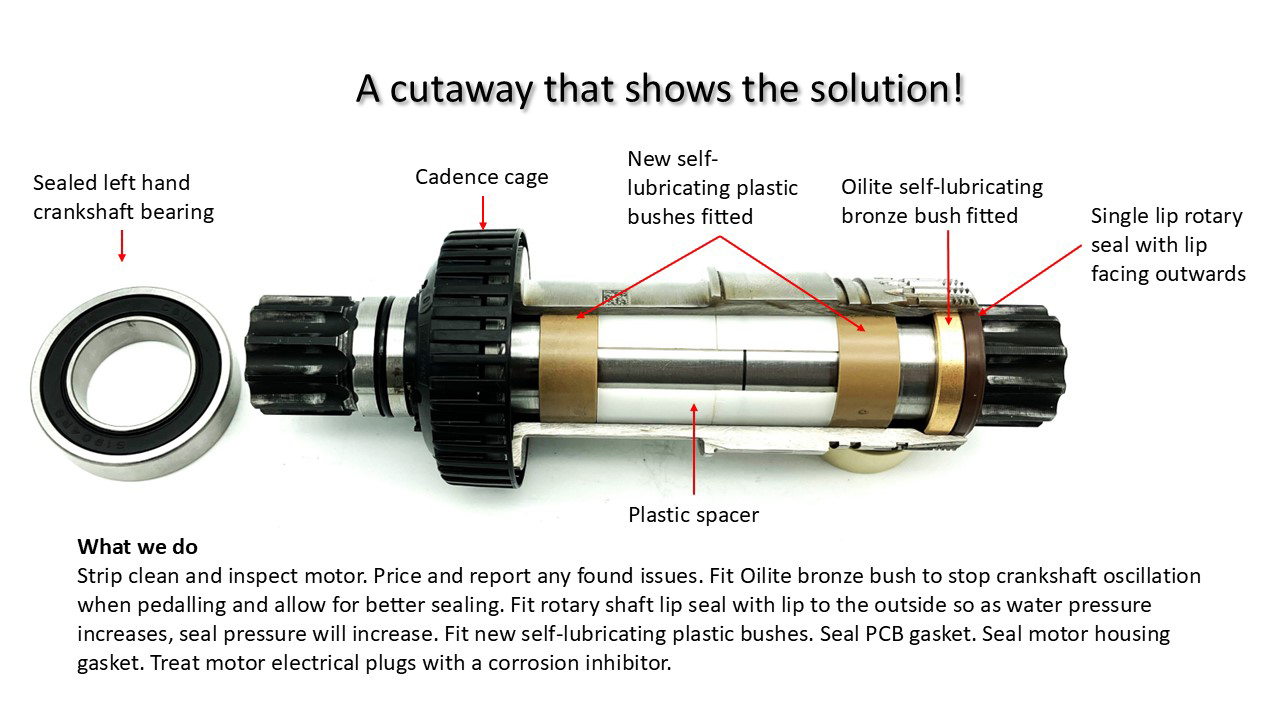

- Motor is disassembled and the complete crankshaft assembly removed.

- Self-lubricating plastic crankshaft support bushes are replaced in the torque tube to stabilise crankshaft play.

- The original torque tube sealing ring is removed and an Oilite self-lubricating bronze bush is fitted to ensure maximum crankshaft support. This stops crankshaft oscillation and aids sealing.

- After the Oilite bush, we fit a single-lip rotary shaft seal, with the lip facing outwards to stop water ingress into the crankshaft and torque tube area. This stops rust damage to the crankshaft bearing surface, premature failure of the crankshaft support bushes, and internal damage to the printed circuit board (PCB) and all other components.

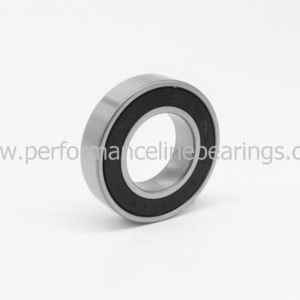

- The left hand crankshaft bearing is replaced with a double-sealed bearing to prevent water ingress into or through this bearing.

- Waterproof long life grease is packed between outer bearings and motor covers. This helps stop water sitting in these areas and seeping into the outer bearings.

- We also remove the PCB and add a silicone coating to the plug assembly gasket seal.

- Silicone gasket sealant is also added to the aluminium motor cover gasket. Water ingress into this area corrodes the gasket faces of the magnesium motor cases.

- Finally, we treat and coat the motors’ electric socket pins to limit corrosion.

| Weight | 160 oz |

|---|---|

| Dimensions | 10 × 10 × 10 in |

Mahle 1.1 Sprag clutch bearing. Part No PLM00730

Mahle 1.1 Sprag clutch bearing. Part No PLM00730